Maui Platform A, New Zealand

By Doug St George.

|

|

From 1974 to 1979 I worked on this project, initially as an Instrumentation

Engineer, then in charge of Offshore Hookup and later became one of two

Platform Superintendents during the completion of well drilling and startup

of production. This was a major engineering project, and I have an extensive collection

of photos taken during that time. I hope that you find this interesting, please

feel free to use any material on this page. Some pictures are clickable for a larger image.

Location

The Maui gas field lies 21 miles west of the North Island of New Zealand,

off the Taranaki coast, in view of Mt Taranaki (or Mt Egmont). The field was

drilled in 1969 and 1970 and assessed to hold 8,428,000 million cubic feet

of gas and recoverable condensate (liquid) of 75 million barrels. It was one

of the largest continous gas fields ever discovered.

Construction

Construction started in 1974, and the steel jacket was built at Tsu, in

Japan. The steel jacket was designed to be self floating, for towing to

New Zealand, and was designed for 354 feet water depth and 75 ft storm wave.

Other design conditions include earthquake and storm winds. Specialist welding

and heat treating was required for steel thicknesses of several inches

with all welds X-rayed. Two of the jacket legs contained flotation chambers

which would be flooded in sequence during positioning at the Maui field.

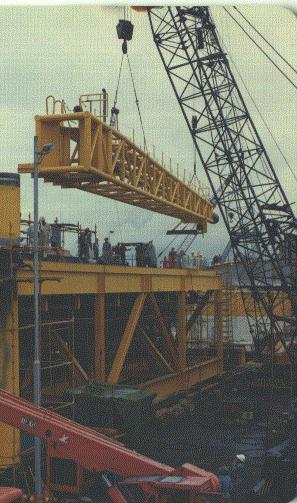

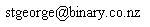

The flare boom

is fitted.

The flare boom

is fitted.

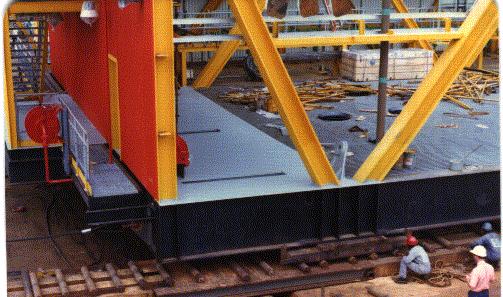

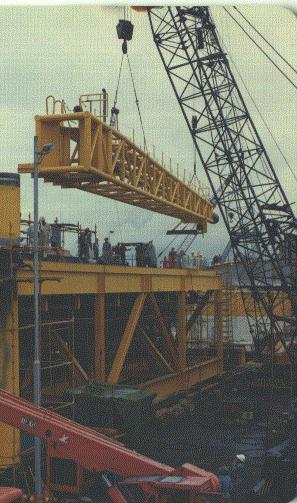

A module rolls

out onto a sea-going barge.

A module rolls

out onto a sea-going barge.

The modules containing living quarters and production facilities were

built in Singapore, at Jurong and Sembawang shipyards, placed on barges and

towed to New Zealand.

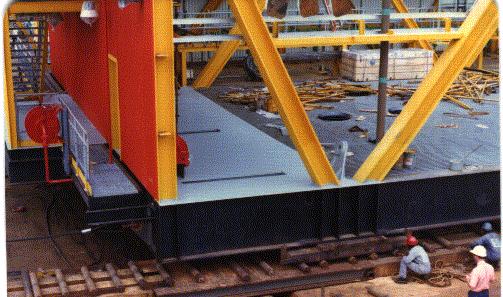

Once the steel jacket was located in position and

settled on the seafloor, an extensive piling program began to firmly

locate the structure against earthquakes and severe storm conditions. The 28

piles were made of 4 inch thick 48 inch diameter steel pipes, welded

together and driven into the seabed using a steam hammer on a

crane barge.

1200 miles of open ocean caused delays to the project as there were

very few workable days when the sea was settled enough for piling work

to continue. A helipad was attached to the jacket to allow crew changes

when the crane barge could not lie alongside. The original crane barge

Atlas supplied by Brown & Root was replaced by the Blue Whale,

a 1200 ton lift crane mounted on a converted 47,000 ton bulk carrier and operated

by Marine Offshore Contractors of Switzerland.

(Picture from Tyler Andersen)

(Picture from Tyler Andersen)

Offshore Hookup

Once the jacket piling was completed,

(Picture from Tyler Andersen)

the tank decks were welded in place

followed by the modules. Each module weighed up to 600 tons. The three

story living quarters for 60 persons (all men in those days) was fitted

with a helideck on the top. After the living quarters was placed, 60 men

were living in it 7 days later, with electricity, sewerage and other

services functional.

(Picture from Tyler Andersen)

the tank decks were welded in place

followed by the modules. Each module weighed up to 600 tons. The three

story living quarters for 60 persons (all men in those days) was fitted

with a helideck on the top. After the living quarters was placed, 60 men

were living in it 7 days later, with electricity, sewerage and other

services functional.

(Picture from Tyler Andersen)

(Picture from Tyler Andersen)

Offshore hookup of piping, process equipment and structural components

continued during the drilling phase when 14 wells were drilled and cased,

using directional drilling techniques to ensure full coverage of the large

field 8,800 feet below. During this time, pipe laying barges laid the 24 inch

gas line and 10 inch condensate line over the 21 miles of seabed to the

onshore production plant.

Offshore hookup of piping, process equipment and structural components

continued during the drilling phase when 14 wells were drilled and cased,

using directional drilling techniques to ensure full coverage of the large

field 8,800 feet below. During this time, pipe laying barges laid the 24 inch

gas line and 10 inch condensate line over the 21 miles of seabed to the

onshore production plant.

Many of the personnel working on the platform

commuted daily by helicopter or lived on the Blue Whale as

the platform accomodation was filled with drilling crews.

Startup

The first well was tested by flaring in June 1978 and later that year

the gas and liquid pipelines were flushed out with gas from the production

facilities. The platform moved into production as the remaining wells were drilled

and completed, and the onshore production equipment was commissioned.

The first well was tested by flaring in June 1978 and later that year

the gas and liquid pipelines were flushed out with gas from the production

facilities. The platform moved into production as the remaining wells were drilled

and completed, and the onshore production equipment was commissioned.

The processing equipment on the platform uses low temperature separators

to initially separate gas and condensate to be sent ashore in the two

pipelines. Onshore, the gas is dried further and the liquid processed to

manufacture LPG and condensate suitable for conversion into petrol and

other refinery products. A large percentage of the gas is used in the

synthetic petrol plant in Taranaki.

Today

The Maui Platform A continues to produce gas and condensate, and the second

Maui Platform B has been installed a further 10 miles offshore to extract

gas, oil and condensate from the other major part of the field. Full

production was expected to continue until about 2015 when the field's

recoverable reserves will be mostly depleted, but the gas production was cut back in 2006.

More photos

Here is a Powerpoint show on Maui Platform A 1976-1979 and the Otahuhu Gas Turbine Power Station 1968-69.

Download here: Maui Platform A.pps is 9 MB and

the Otara Gas Turbine Station.pps is 2.7 MB. Tip: right-mouse Copy Link Location. Open MS Office Powerpoint. File , Open, Ctrl V to paste the web location and go.

email contact

Back to the Top

Binary Systems

The flare boom

is fitted.

The flare boom

is fitted.

A module rolls

out onto a sea-going barge.

A module rolls

out onto a sea-going barge.

Offshore hookup of piping, process equipment and structural components

continued during the drilling phase when 14 wells were drilled and cased,

using directional drilling techniques to ensure full coverage of the large

field 8,800 feet below. During this time, pipe laying barges laid the 24 inch

gas line and 10 inch condensate line over the 21 miles of seabed to the

onshore production plant.

Offshore hookup of piping, process equipment and structural components

continued during the drilling phase when 14 wells were drilled and cased,

using directional drilling techniques to ensure full coverage of the large

field 8,800 feet below. During this time, pipe laying barges laid the 24 inch

gas line and 10 inch condensate line over the 21 miles of seabed to the

onshore production plant.

The first well was tested by flaring in June 1978 and later that year

the gas and liquid pipelines were flushed out with gas from the production

facilities. The platform moved into production as the remaining wells were drilled

and completed, and the onshore production equipment was commissioned.

The first well was tested by flaring in June 1978 and later that year

the gas and liquid pipelines were flushed out with gas from the production

facilities. The platform moved into production as the remaining wells were drilled

and completed, and the onshore production equipment was commissioned.